Lean Manufacturing Tools Fishbone

Posted : adminOn 4/4/2018

Lean Manufacturing Principles form the underpinning roadmap of Lean. No plan can be achieved without a roadmap: a plan of action, which supports clear guidelines and principles – and when incorporating lean, the same applies. Lean Manufacturing Principles are derived from the Toyota Production System (TPS) and follow five concepts. • Understand value in the eyes of the Customer • Understand the Value Stream • Make the Value Stream Flow • Create Pull • Continuously Improve Understand Value in the Eyes of the Customer All Businesses must delight customers in order to retain their own customer base, and indeed create competitive advantage. Noriaki Kano mentioned, that in order to be competitive, companies must aim to provide the customer with their basic needs but also create that wow factor – the delight factor, which they want again and again. It is clear then, that companies must understand their customer’s needs, in order to provide them with what they want.

This is no different in Lean. Companies must understand what customers actually want from them – what is it that they see of value. Only when we know this, we can understand which processes are aligned to providing the customer with value and which are not. New Balance 9000 Elliptical Trainer Manual more.

Understand the Value Stream – Map it! Understanding the Value Stream is the next step. This is done by mapping all the steps involved from Customer order to delivery of product / service to the customer. Here, extensive detail must go into understanding the cycle time of each step, rework%, lost time, uptime of machines (where applicable),number of staff members involved in the task, and other information. Your goal is to see, so understanding accurate data will also give you a few clues as to any anomalies going on and where the waste is (Remember – going to the source to find facts!) This data helps you understand where potential opportunities lie in order to make improvements to that Value Stream. Are there silos of information, inventory, rework, breakdowns of machines?

Are there too many people operating a process? Is the cycle time in the order process too long? The VSM will show this information and flow of product, allowing everyone to see it clearly in a pictorial format. Make it Flow How do you make a Value Stream flow? By removing the waste or NVA!

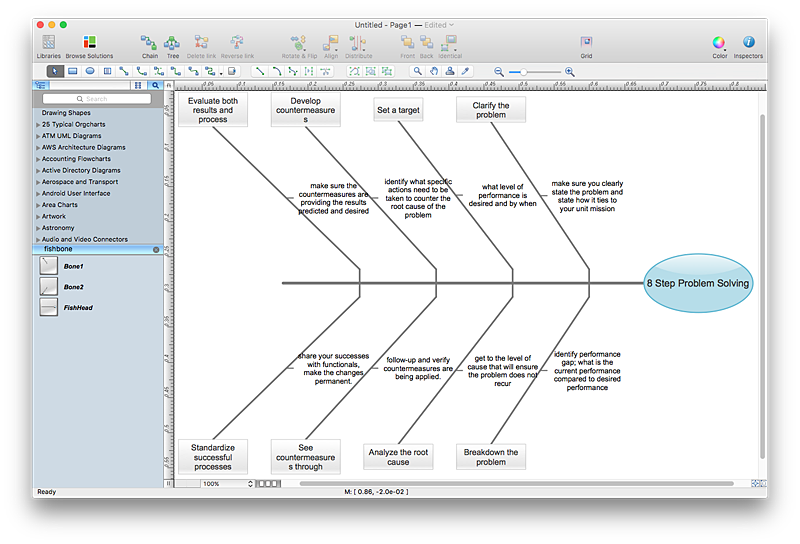

The Fishbone Diagram AKA Cause & Effect Diagram, identifies possible causes for an effect or problem. Learn about the other 7 Basic Quality Tools at ASQ.org. The Fishbone Diagram can incorporate metrics but is primarily a visual tool for. In manufacturing settings the. Need a tool to create Fishbone. It has been suggested to return to the roots of the tools. How do Fishbone diagrams solve manufacturing problems? Lean Manufacturing Diagrams Lean.

If you remove waste in a Value Stream, you shorten the lead time. Once you have identified improvement opportunities in your current State VSM, these become your for the next 6 – 12 months. Each Kaizen is a targeted improvement project, designed to eliminate the waste in the Value Stream. The Kaizens should be completed in the required timescale. – The result: a leaner value stream with shortened lead-times, which flows information and product through the business a lot quicker and smoother. Create Pull So far, we have followed the first three of the five Lean Manufacturing Principles: Customer requirements and value understood?